WORK REPORT

Your One-Stop Solution for All Work Process Insights

A Powerful Tool to Centralize and Streamline Tracking of Garment Manufacturing Processes

- Provides real-time insights into every order — from raw material procurement to final delivers

- Offers a seamless, end-to-end workflow for manufacturing management

Monitors work statuses, material usage, and timelines efficiently

Tracks job worker activities across all production stages

Ensures smooth, error-free manufacturing execution

FEATURES

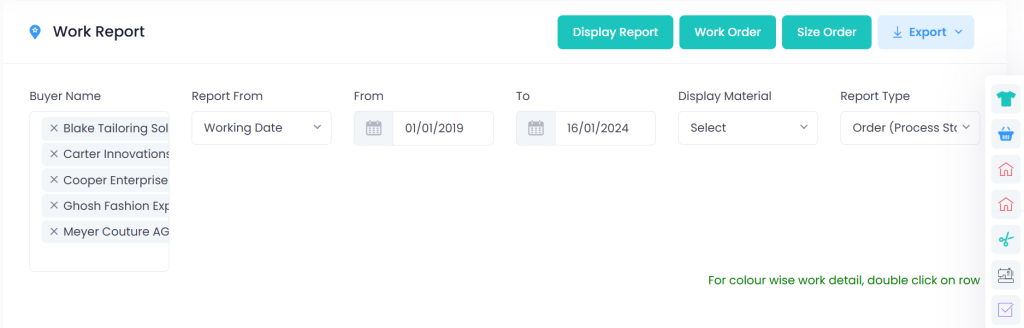

Customizable Filters for Precise Information Retrieval

This Work Report feature allows you to efficiently grab the exact information you need using customizable filters. You can select multiple Buyers or All at once and apply various filters based on:

-

Date Range (From,To)

-

Material Types (such as Fabric, Accessory, All or None)

-

Process Status (Process Started or Process Not Started)

-

Report From (Order Date, Delivery Date or Working Date)

-

Work Order (In which process Order to View the report)

-

Size Order (In which size order to view the report)

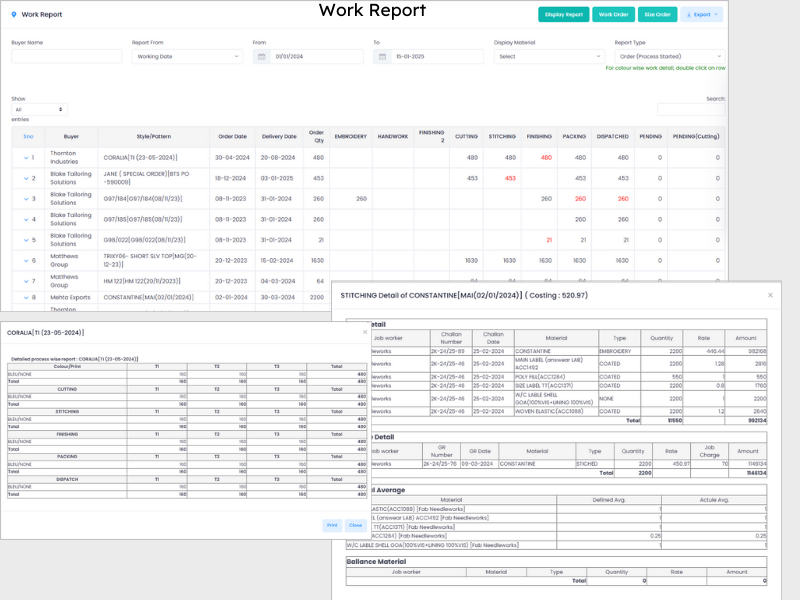

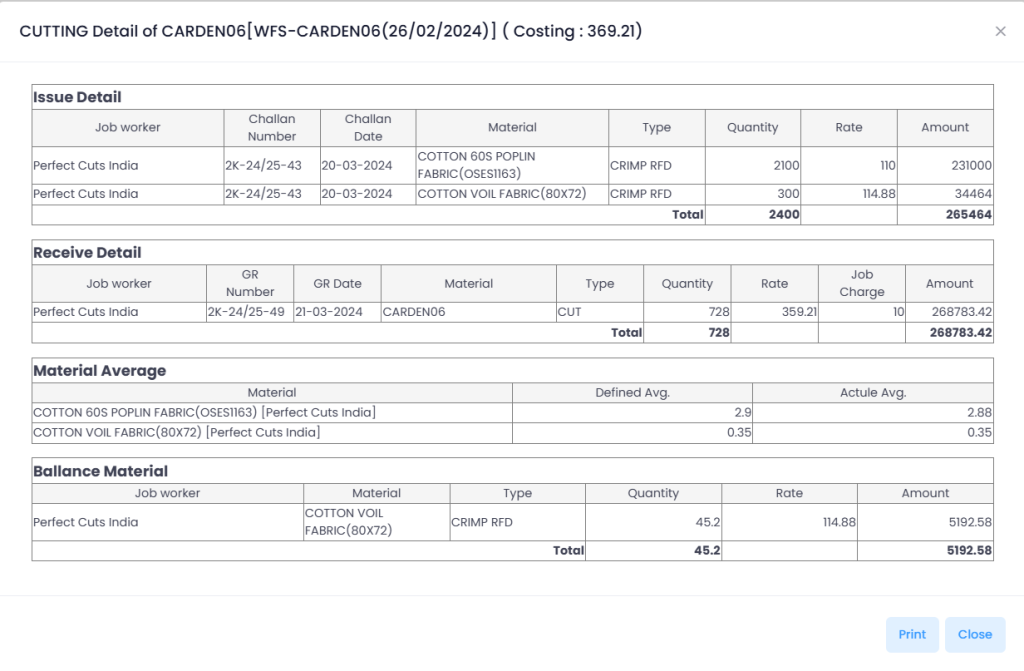

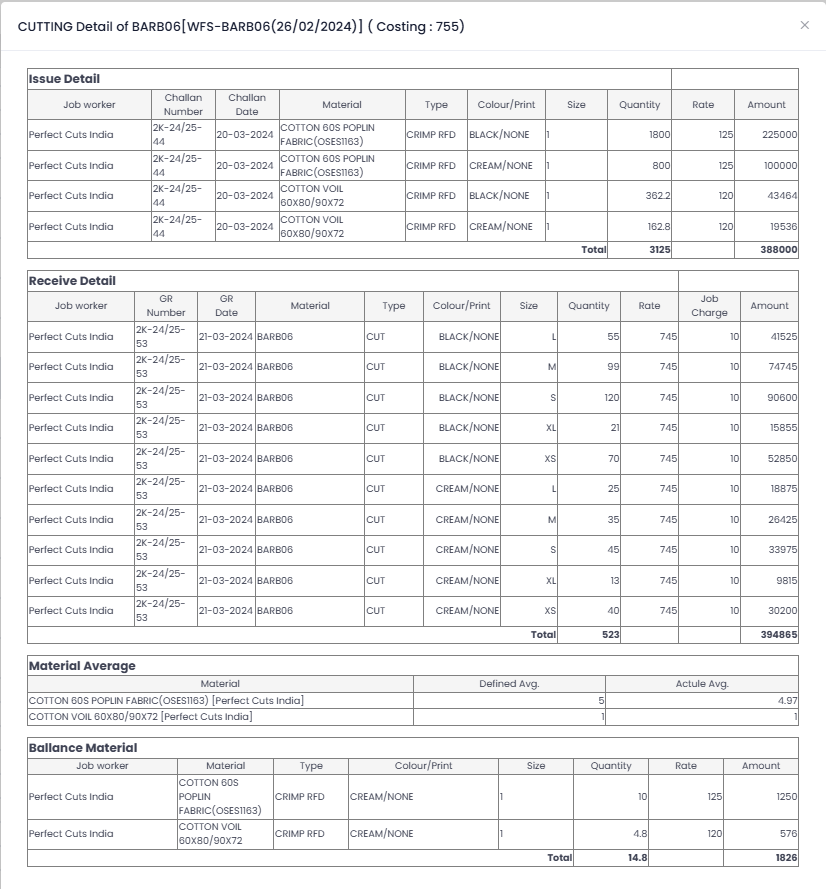

Detailed Process Tracking

This feature provides a comprehensive overview of the status of various manufacturing processes involved in garment production, such as , Cutting, Stitching, Dyeing etc.

The Work Report delivers detailed information about each process, including

-

Materials Issued

What materials were provided for the process, their type, quantity, and associated details like rates and amounts.

-

Job Worker Details

The name of the job worker handling the process, along with challan numbers and issue dates.

-

Material Received

Records of the materials received after the process, including quantities, types, and updated rates.

-

Process Charges

Job worker charges per piece and total costs for the process.

-

Defined vs. Actual Material Average

A comparison between the expected material usage and the actual consumption during the process.

-

Balance Material

Information about unused materials still with the job worker, including quantities and other relevant details.

This functionality allows businesses to:

-

Monitor each step of production with precision.

-

Identify delays or bottlenecks in any specific process.

-

Keep a real-time track of materials issued and received for each process.

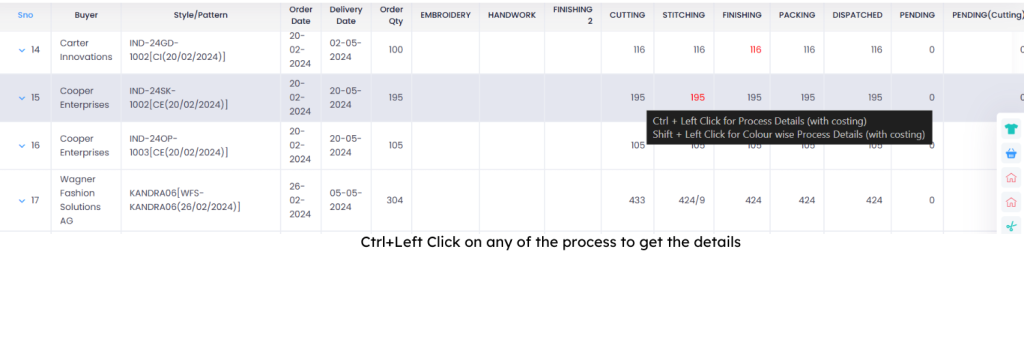

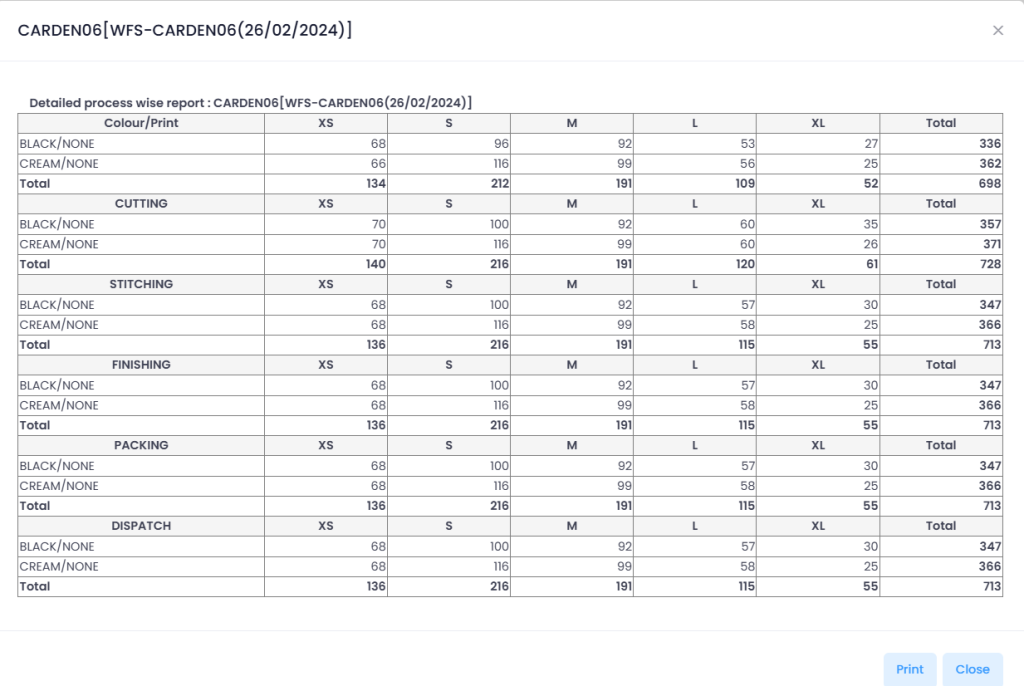

Color-Wise Process Details at Your Fingertips

One of the most insightful features of the Work Report is its ability to provide color-wise work details with costing for any process, ensuring comprehensive tracking and minimizing errors. By simply Shift + Left clicking on any process column , users can access a detailed popup with the following information:

-

Color/Print Breakdown

View the styles issued in different colors or prints.

-

Size Distribution

See the sizes in which each color/print was issued.

-

Quantity Details

Get the exact quantity received after each process for each size and color/print.

-

Total Quantity Summary

A consolidated total of all the quantities across sizes and colors/prints.

or simply double left click for a color-wise view without costing

This feature ensures that businesses:

-

Maintain error-free production by having accurate data on quantities issued and completed.

-

Track the progress of specific colors and sizes, ensuring adherence to order requirements.

-

Avoid discrepancies or mismanagement by having a precise log of all activities related to the style.

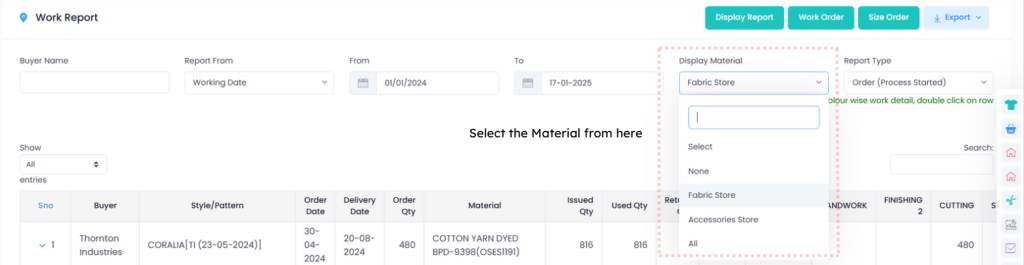

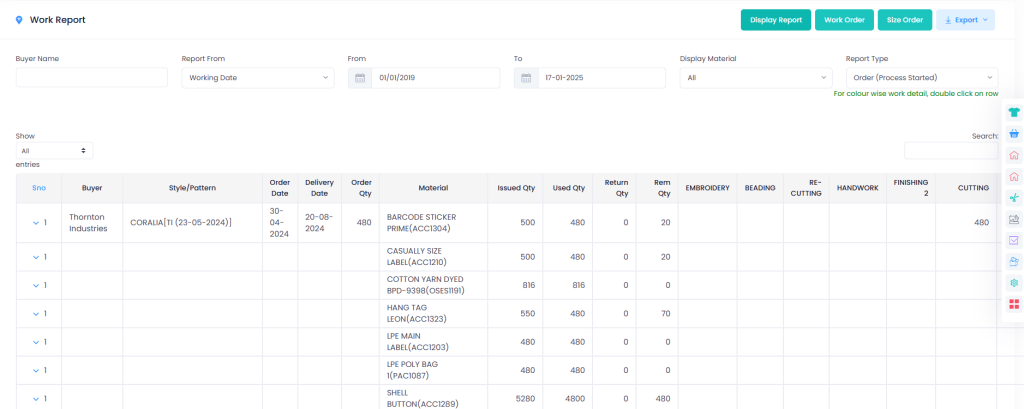

Material Insights

A Comprehensive Tracking of Fabric and Accessories

This feature allows users to gain a deeper understanding of the materials used in each style order, offering a clear and organized view of all relevant details. Here's how it works:

-

Filter by Type of Material

Users can select from the following options

1-Fabric Store: Displays a detailed breakdown of the fabric used in a particular style order, including:

1-Fabric type.

2-Quantity issued.

3-Specifications or unique identifiers.

2-Accessory Store: Shows comprehensive details of all accessories used in the style order, such as:

1-Buttons, zippers, or other components.

2-Quantities issued.

3-All: Combines the details of both fabrics and accessories to provide a complete material overview for the selected style order.

Advantages of Material Insights

-

Enhanced Material Management

Easily track the exact materials used for each order, ensuring accountability and transparency.

-

Detailed Breakdown

Gain insights into the types and quantities of materials issued, making inventory management more efficient.

-

Customizable Views

Flexibly switch between fabric, accessories, or both, depending on the user's requirements.

-

Seamless Manufacturing Process

Having a clear record of materials ensures that all components are accounted for, reducing errors or rework.

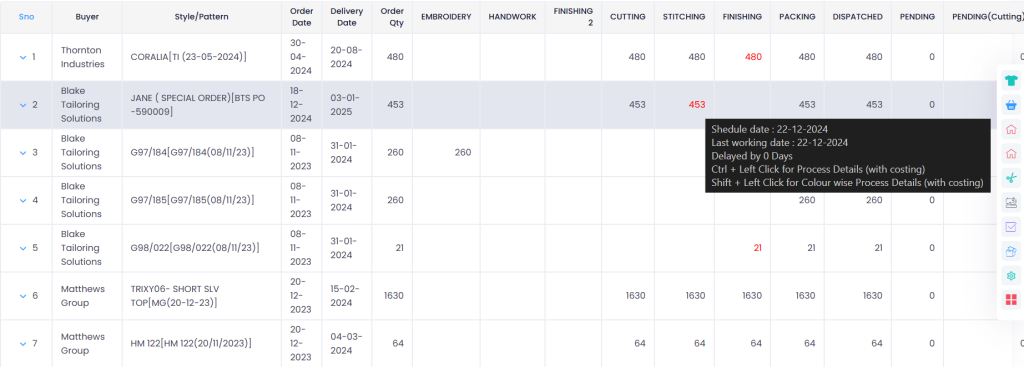

Delay Alerts

The Delay Alerts feature is a proactive tool that helps businesses stay ahead of potential bottlenecks in the manufacturing process. Here's how it works and the advantages it offers:

-

Color-Coded Indicators

Delays are highlighted visually with Red color for quick identification

-

Hover for Details

By simply hovering over the highlighted section, users can view additional information, such as:

1-The duration of the delay.

2-Scheduled dates for the process versus the actual status.

3-Insight into which stages of the process are causing the delay -

Instant Notifications

With this feature, users are immediately made aware of any deviations from the schedule, enabling swift corrective actions.

Benefits of Delay Alerts

-

Improved Time Management

Identify and address delays promptly to keep the manufacturing process on track.

-

Enhanced Visibility

Clear and intuitive visuals provide a snapshot of process timelines and potential risks.

-

Proactive Decision-Making

Prevent further disruptions by intervening early in delayed processes.

-

Customer Satisfaction

Ensure timely deliveries by minimizing delays, leading to better client relationships.

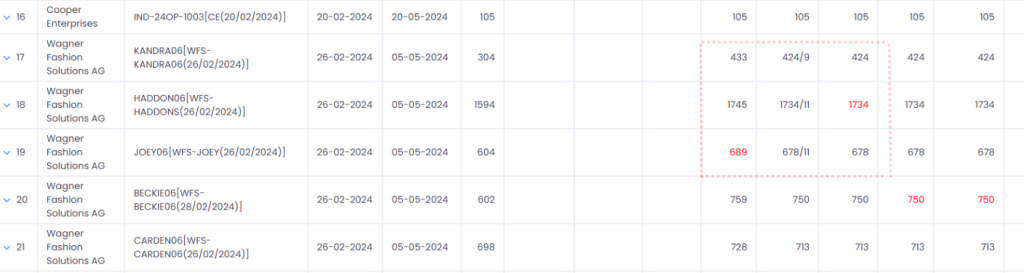

Rejection Tracking

This feature provides a clear and transparent way to track rejected pieces during any process in the manufacturing workflow. Here's how it works

-

When defective or disfigured pieces are identified, users can mark them as rejected during the goods receiving phase of the process.

-

The work report automatically updates to reflect the total pieces received alongside the number of rejected pieces.

-

For example, if 450 pieces were expected after stitching but 15 were defective and rejected, the report will display: 450/15 under the stitching column for that order.

Benefits of Rejection Tracking

-

Transparency

Keeps all stakeholders informed about process outcomes, including challenges encountered during production.

-

Process Insights

Allows businesses to analyze trends in defects, enabling corrective measures to minimize future rejections.

-

Accountability

Provides clear visibility into the rejected quantities for each process, helping to identify areas that require attention or improvement.